Ferrules / Sleeves

Ferrules are used in numerous applications:

- Construction engineering

- Fishing industry

- Shipyards

- Hoisting industry

- Metallurgy

- Mining

- Conveyor technology

- Petroleum industry

- Medical technology

- Aircraft industry

- Car production

- Marine technology

- Leisure activities

|

|

|

|

|

|

Aluminum EN13411-3 Form A Ferrules

|

|

| Rope

Size IWRC (WC) |

FC(HC) |

Part # |

Sleeve

Size (mm) |

Weight

(lbs) PER 100 pcs |

Packaging

per box |

| 1/32” |

|

RCAL01 |

1 |

0.022 |

1000 |

| 3/64” |

3/64” |

RCAL015 |

1.5 |

0.046 |

1000 |

| 1/16” |

1/16” |

RCAL02 |

2 |

0.066 |

1000 |

| 3/32” |

3/32” |

RCAL025 |

2.5 |

0.110 |

1000 |

|

|

RCAL03 |

3 |

0.185 |

1000 |

| 1/8” |

1/8” |

RCAL035 |

3.5 |

0.290 |

1000 |

|

5/32” |

RCAL04 |

4 |

0.398 |

1000 |

| 5/32” |

|

RCAL045 |

4.5 |

0.574 |

1000 |

|

3/16” |

RCAL05 |

5 |

0.785 |

1000 |

| 7/32” |

7/32” |

RCAL06 |

6 |

1.29 |

1000 |

|

1/4” |

RCAL065 |

6.5 |

1.66 |

1000 |

| 1/4” |

|

RCAL07 |

7 |

2.10 |

1000 |

|

5/16” |

RCAL08 |

8 |

3.01 |

1000 |

| 5/16” |

|

RCAL09 |

9 |

4.36 |

500 |

|

3/8” |

RCAL10 |

10 |

5.81 |

500 |

| 3/8” |

7/16” |

RCAL11 |

11 |

7.88 |

300 |

| 7/16” |

|

RCAL12 |

12 |

10.08 |

200 |

|

1/2” |

RCAL13 |

13 |

13.13 |

200 |

| 1/2” |

9/16” |

RCAL14 |

14 |

16.17 |

200 |

| 9/16” |

5/8” |

RCAL16 |

16 |

24.42 |

100 |

| 5/8” |

|

RCAL18 |

18 |

34.98 |

100 |

|

3/4” |

RCAL20 |

20 |

47.74 |

50 |

| 3/4” |

7/8” |

RCAL22 |

22 |

64.24 |

50 |

| 7/8” |

|

RCAL24 |

24 |

82.72 |

30 |

|

1” |

RCAL26 |

26 |

105.82 |

30 |

| 1” |

1-1/8” |

RCAL28 |

28 |

132.66 |

25 |

|

|

RCAL30 |

30 |

161.48 |

25 |

| 1-1/8” |

1-1/4” |

RCAL32 |

32 |

197.34 |

20 |

|

|

RCAL34 |

34 |

237.6 |

10 |

|

1-3/8” |

RCAL36 |

36 |

280.50 |

10 |

|

1-1/2” |

RCAL38 |

38 |

327.80 |

10 |

|

|

RCAL40 |

40 |

381.48 |

1 |

| 1-1/2” |

|

RCAL42 |

42 |

444.40 |

1 |

|

1-3/4” |

RCAL44 |

44 |

509.08 |

1 |

|

|

RCAL46 |

46 |

562.54 |

1 |

|

1-7/8” |

RCAL48 |

48 |

662.20 |

1 |

|

2” |

RCAL50 |

50 |

748.00 |

1 |

|

|

RCAL52 |

52 |

838.86 |

1 |

|

2-1/8” |

RCAL54 |

54 |

906.40 |

1 |

|

2-1/4” |

RCAL56 |

56 |

1049.84 |

1 |

|

|

RCAL60 |

60 |

1293.60 |

1 |

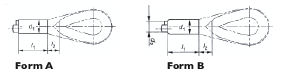

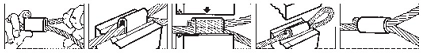

Splicing instructions for Aluminum Ferrules (Form A + B) according to EN 13411-3

|

|

-

Allocation ferrule to wire rope

Select the appropriate ferrule according to our splicing

table. Wire rope constructions with a metallic crosssectional

area factor of less than 0,283 should not be

used. These splicing instructions work for wire rope

constructions according to EN 12385-4. Wire rope

constructions with a tensile grade above 1960 N/mm²

should not be used.

-

Preparation of the rope end

Ensure that the rope remains in lay after cutting and that

no impurities (adhesive tape, etc.) will be within the pressed

ferrule.

-

Selection of swaging dies

Form A should be swaged in approved Universal or

Cylindrical dies. Form B should only be swaged in approved

and specially marked rounded dies. Ensure that the ferrule

code No. and the No. of your swaging die set correspond.

-

Installation and condition of the tooling

Swaging die faces with corresponding numbers need to

be precisely aligned in the die pocket. Dies with worn out

cutting edges do no longer assure an accurate swaging

procedure according to EN 13411-3 and should be

removed from service.

-

Swaging procedure

The procedure shall be carried out by a competent person

trained in ferrule securing. Ferrules 6mm and higher need

to be swaged in hydraulic swagers. Smaller sizes might as

well be swaged with our hand swaging tools.

-

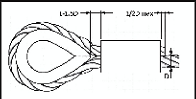

Feed the wire rope through the ferrule in order to provide

the required eye. Return the rope end and form the loop.

If no thimble is fitted, the distance from the ferrule to the

bearing-point should be at least 15 times the rope diameter.

-

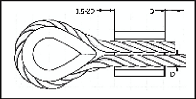

The rope diameter D should be the guide value of how far

the dead end of the rope should protrude out of the ferrule

before swaging. This needs to be checked after each swaging

procedure and adjusted if necessary, according to the type

of wire rope, tensile grade and diameter.

-

For satisfactory results you need to first clean and then

lubricate the die bore with mineral grease (no oil) before

each swaging procedure.

-

Place the ferrule centered and ensure that it is truly

vertical within the Die bore.

-

Cease Pressing immediately die faces meet. Do not repress

‘flash’ back into splice.

-

For thimbles without points the gap between the thimble

end and the pressed ferrule should be about 1,5 time the

wire rope diameter D. For thimbles with points the gap

should be 1 time the wire rope diameter D.

-

After swaging the rope ‘dead’end for form A + B should

protrude from the pressed ferrule by up to half a rope

diameter. For ropes that are severed by annealing process,

ensure that the annealed rope portion remains outside the

ferrule after pressing.

-

Ferrules after Swaging

On completion of swaging operation, resultant ‘flash’ must

be removed. Swaging dies in good condition permit to

either break the ‘flash’ off by hand or with a small hammer.

Any residual edge may be filed or otherwise smoothed were

required. Every pressed ferrule needs to be checked for

correct dimensions and position of the ‘dead’ rope end.

The temperature limits when used with a fibre core wire

rope are -40° to +100° C

The temperature limits when used with a steel core wire

rope are -40° to +150° C

-

Marking the ferrule

If the Ferrule secured Eye Termination (FSET) forms part

of a wire rope assembly other than a sling:

-

the ferrule shall be legibly and indelibly marked with the

FSET manufacturer’s name, symbol or mark; and

-

the assembly shall be legibly and durably marked with

the traceability code identifying the assembly with the

certificate in 7.2. of EN 13411-3.

For FSET forming part of a sling you will find further

details in the standard EN 13141-1.

-

Remark

Our ferrule-secured system is in accordance with the type

testing procedure of EN 13411.3 point 5.1.2. for steel wire

ropes defined in EN 12385-4.

Ferrule secured eye terminations should be removed from

service if badly distorted or if body is reduced to 95 % of its

original diameter.

We reserve the right to amend technical data.

|

|

| Before Swaging |

After Swaging |

|

|

Aluminum EN 13411-3 Form A Oval Ferrules

|

|

|

Rope Ø mm nominal

d |

Rope Ø mm measured |

ferrules according to EURONORM 13411-3 |

|

single layer round strand ropes with fibre core and cable

laid ropes |

single layer round strand ropes with IWRC

and rotation-resistant round strand ropes |

spiral strands (2 ferrules) |

| min. |

max. |

metallic cross sectional area factor C

min. 0,283 |

C up to 0,487 |

C greater 0,487 up to 0,613 |

C min 0,613 |

| 6,5 |

6,5 |

6,9 |

- |

- |

8 |

8 |

| 7 |

7,0 |

7,4 |

- |

8 |

9 |

9 |

| - |

7,5 |

7,9 |

8 |

9 |

9 |

10 |

| 8 |

8,0 |

8,4 |

8 |

9 |

10 |

10 |

| - |

8,5 |

8,9 |

9 |

10 |

10 |

11 |

| 9 |

9,0 |

9,5 |

9 |

10 |

11 |

11 |

| - |

9,6 |

9,9 |

10 |

11 |

11 |

12 |

| 10 |

10,0 |

10,5 |

10 |

11 |

12 |

12 |

| - |

10,6 |

10,9 |

11 |

12 |

12 |

13 |

| 11 |

11,0 |

11,6 |

11 |

12 |

13 |

13 |

| - |

11,7 |

11,9 |

12 |

13 |

13 |

14 |

| 12 |

12,0 |

12,6 |

12 |

13 |

14 |

14 |

| - |

12,7 |

12,9 |

13 |

14 |

14 |

16 |

| 13 |

13,0 |

13,7 |

13 |

14 |

16 |

16 |

| - |

13,8 |

13,9 |

14 |

16 |

16 |

18 |

| 14 |

14,0 |

14,7 |

14 |

16 |

18 |

18 |

| - |

14,8 |

15,9 |

16 |

18 |

18 |

20 |

| 16 |

16,0 |

16,8 |

16 |

18 |

20 |

20 |

| - |

16,9 |

17,9 |

18 |

20 |

20 |

22 |

| 18 |

18,0 |

18,9 |

18 |

20 |

22 |

22 |

| - |

19,0 |

19,9 |

20 |

22 |

22 |

24 |

| 20 |

20,0 |

21,0 |

20 |

22 |

24 |

24 |

| - |

21,1 |

21,9 |

22 |

24 |

24 |

26 |

| 22 |

22,0 |

23,1 |

22 |

24 |

26 |

26 |

| - |

23,2 |

23,9 |

24 |

26 |

26 |

28 |

| 24 |

24,0 |

25,2 |

24 |

26 |

28 |

28 |

| - |

25,3 |

25,9 |

26 |

28 |

28 |

30 |

| 26 |

26,0 |

27,3 |

26 |

28 |

30 |

30 |

| - |

27,4 |

27,9 |

28 |

30 |

30 |

32 |

| 28 |

28,0 |

29,4 |

28 |

30 |

32 |

32 |

| - |

29,5 |

29,9 |

30 |

32 |

32 |

34 |

| 30 |

30,0 |

31,5 |

30 |

32 |

34 |

34 |

| - |

31,6 |

31,9 |

32 |

34 |

34 |

36 |

| 32 |

32,0 |

33,6 |

32 |

34 |

36 |

36 |

| - |

33,7 |

33,9 |

34 |

36 |

36 |

38 |

| 34 |

34,0 |

35,7 |

34 |

36 |

38 |

38 |

| - |

35,8 |

35,9 |

36 |

38 |

38 |

40 |

| 36 |

36,0 |

37,8 |

36 |

38 |

40 |

40 |

| - |

37,9 |

37,9 |

38 |

40 |

40 |

44 |

| 38 |

38,0 |

39,9 |

38 |

40 |

44 |

44 |

| 40 |

40,0 |

42,0 |

40 |

44 |

48 |

48 |

| - |

42,1 |

43,9 |

44 |

48 |

48 |

52 |

| 44 |

44,0 |

46,2 |

44 |

48 |

52 |

52 |

| - |

46,3 |

47,9 |

48 |

52 |

52 |

- |

| 48 |

48,0 |

50,4 |

48 |

52 |

- |

- |

| - |

50,5 |

51,9 |

52 |

- |

- |

- |

| 52 |

52,0 |

54,6 |

52 |

- |

- |

- |

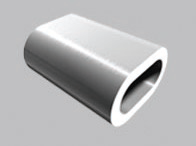

Splicing Instructions for Flemish Eye Sleeves According to EN 13411-3

|

|

-

Allocation ferrule to wire rope

Select the appropriate sleeve according to our

splicing table. Standard Flemish eye carbon steel

sleeves are recommended for use with 6x19,

6x37 or 6x3, IPS or XIP (EIP), XXIP (EEIP)

RRL, FC or IWRC wire rope.

-

Preparation of the rope

Slide the ferrule down the rope.

Un-lay the wire rope. For IWRC rope 3 strands

and core in one group and 3 strands in the other

group.

For FC rope un-lay with 3 strands in each group

and cut away the fibre core.

Cross and lay the one group of strands into

the other group of strands forming a natural

weave. Continue to reweave the group of strands

together to form the eye. The remaining tails

must be as long as the cylindrical part of the

ferrule.

At the end of the eye collect the tails around the

outside of rope dispersing equally and slide the

ferrule over the tails and as far up towards the

eye as possible.

-

Installation and condition of the tooling

Swaging die faces with corresponding numbers

need to be precisely aligned in the die pocket.

-

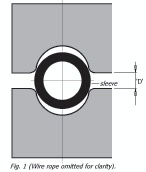

Swaging procedure

A competent person, trained in ferrule securing

shall carry out the procedure.

Clean and lubricate the bore of the dies with

mineral grease (or high pressure oil) before the

swaging procedure.

Splicing instructions for

Flemish Eye sleeves

according to EN 13411-3

Put the ferrule in the lower half of the cylindrical

die (STEP 1) and close the dies only so far that

the original gap between the Die faces reduces by

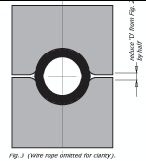

50 % (STEP 2). Open the dies again and turn

the ferrule by 45° to 75°. Re-press again and close

up to ¼ of the original diameter (STEP 3).

Ensure after STEP 3 procedure that sharp edge

flashing is not occurring, then close the Dies. If

sharp flash is predicted, repeat STEP 3.

Open the dies again and turn the ferrule by 45°

to 75° until the dies can be completely closed

(STEP 4). During these operations there should

not be any pronounced ‘flash’ production.

When using the conical dies it is important to

position splice centrally in Die bore, in order to

permit sleeve elongation in both directions.

Repeat the operations in the same way in the

conical part (set) of dies.

-

Ferrules after swaging

The temperature limits when used with a steel

core wire rope are -60° to +250° C

-

Marking the ferrule

Use round corner stamps to a maximum depth of

0.015” (1/64). The area for stamping should be

on the side of the sleeve in the plane of the sling

eye and no less than 0.250” (1/4) from either end

of the sleeve.

We reserve the right to amend technical data.

|

|

|

|

|

| Step 1 |

Step 2 |

Step 3 |

Step 4 |

Remarks |

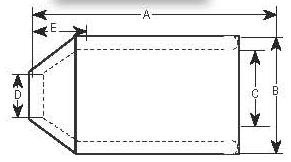

Standard Flemish Eye Carbon Steel Sleeves

|

|

|

|

|

|

|

Before swaging dimensions (in.) |

|

| Part # |

Sleeve Size |

Weight per each |

Packing per box |

A |

B |

D |

E |

G |

After Swage dia. |

| BAZ-06 |

1/4" |

5 |

100 |

1.00 |

0.66 |

0.31 |

0.28 |

0.47 |

0.57 |

| BAZ-08 |

5/16" |

14 |

100 |

1.50 |

0.91 |

0.38 |

0.44 |

0.62 |

0.75 |

| BAZ-10 |

3/8" |

14 |

100 |

1.50 |

0.91 |

0.47 |

0.39 |

0.66 |

0.75 |

| BAZ-11 |

7/16" |

33 |

100 |

2.00 |

1.22 |

0.53 |

0.65 |

0.85 |

1.01 |

| BAZ-13 |

1/2" |

29 |

100 |

2.00 |

1.22 |

0.63 |

0.56 |

0.91 |

1.01 |

| BAZ-14 |

9/16" |

64 |

50 |

2.75 |

1.47 |

0.70 |

0.63 |

1.03 |

1.24 |

| BAZ-16 |

5/8" |

56 |

50 |

2.75 |

1.47 |

0.75 |

0.63 |

1.09 |

1.24 |

| BAZ-19 |

3/4" |

88 |

50 |

3.19 |

1.72 |

0.91 |

0.84 |

1.28 |

1.46 |

| BAZ-22 |

7/8" |

131 |

25 |

3.56 |

2.03 |

1.03 |

1.00 |

1.53 |

1.68 |

| BAZ-26 |

1" |

195 |

20 |

4.00 |

2.28 |

1.16 |

1.13 |

1.75 |

1.93 |

| BAZ-28 |

1-1/8" |

260 |

10 |

4.63 |

2.50 |

1.28 |

1.25 |

1.93 |

2.13 |

| BAZ-32 |

1-1/4" |

35 |

10 |

5.19 |

2.78 |

1.44 |

1.41 |

2.16 |

2.32 |

| BAZ-36 |

1-3/8" |

423 |

Bulk |

5.81 |

3.00 |

1.56 |

1.56 |

2.35 |

2.52 |

| BAZ-38 |

1-1/2" |

49 |

Bulk |

6.25 |

3.25 |

1.71 |

1.69 |

2.62 |

2.71 |

| BAZ-45 |

1-3/4" |

805 |

Bulk |

7.25 |

3.84 |

1.94 |

1.97 |

3.13 |

3.10 |

| BAZ-50 |

2" |

1132 |

Bulk |

8.50 |

4.38 |

2.19 |

2.25 |

3.61 |

3.56 |

| BAZ-57 |

2-1/4" |

1934 |

Bulk |

9.56 |

5.03 |

2.50 |

2.53 |

4.03 |

4.12 |

| BAZ-64 |

2-1/2" |

2350 |

Bulk |

10.50 |

5.50 |

2.75 |

2.88 |

4.50 |

4.50 |

| BAZ-70 |

2-3/4" |

2796 |

Bulk |

11.50 |

5.75 |

3.00 |

3.09 |

4.74 |

4.70 |

| BAZ-76 |

3" |

2937 |

Bulk |

12.00 |

6.00 |

3.25 |

3.38 |

5.00 |

4.96 |

| BAZ-89 |

3-1/2" |

463 |

Bulk |

14.00 |

7.00 |

3.88 |

3.94 |

5.84 |

5.77 |

| BAZ-95 |

3-3/4" |

5493 |

Bulk |

15.00 |

7.50 |

4.06 |

4.25 |

6.31 |

6.23 |

|

BAZ-100 |

4" |

6791 |

Bulk |

16.00 |

8.13 |

4.38 |

4.50 |

6.81 |

6.69 |

|

BAZ-115 |

4-1/2" |

998 |

Bulk |

18.00 |

9.13 |

4.88 |

5.06 |

7.66 |

7.45 |

All sleeves are marked for traceability.

For Flemish eye wire rope splicing made with special processed low

carbon steel for better swage ability. Can be stamped for

identification after swaging without concern for cracking with the

following directions. Use round corner stamps to a maximum depth of

0.015 in. (1/64). The area for stamping should be on the side of the

sleeve in the plane of the sling eye, and no less than 0.250 in. (1/4)

from either end of the sleeve. NOTE: Standard Sleeves are recommended

for use with 6 x 19 or 6 x 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC

or WRC wire rope.

Standard Flemish Eye Carbon Steel Sleeves Specifications

|

|

|

Our carbon steel sleeves are produced with special low carbon

seamless steel, alloyed with the right elements to improve their

mechanical properties and annealed to allow a high degree of

swagability without cracking. For improved corrosion resistance,

sleeves can also be offered galvanized.

All our sleeves are suited for Flemish eye swaging in demanding

rigging, lifting and securing applications.

Our sleeves are independently verified against cracking by accredited

local metallurgical testing laboratories. The sleeves are tested for

composition and compared to others using Energy Dispersive

Spectroscopy and Inductively Coupled Plasma. Sleeves are then

flattened and checked for evidence of no cracking using X-ray

Diffraction.

Mil certificates are available upon request.

|

|

|